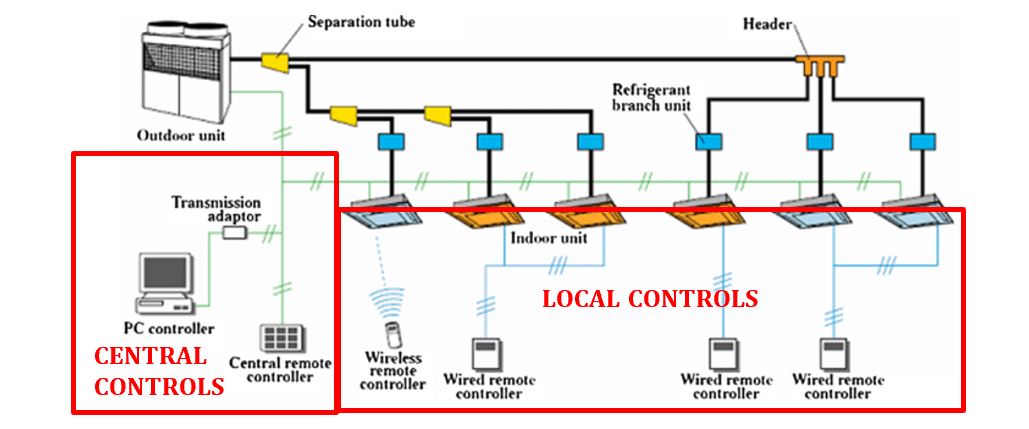

In my first blog on Common VRF (Variable Refrigerant Flow) Installation Issues I focused on issues during mechanical and hardware installation that typically lead problems during startup and pre-functional checkout commissioning. This blog will focus on controls issues identified during commissioning design review which usually lead to issues during start up if not addressed up front during design. As mentioned in the previous article, VRF systems can allow for better comfort and overall satisfaction, but if not properly programmed for the owner’s specific application, can lead to numerous complaints during the first year of occupancy.

Walker Calderwood

Recent posts by Walker Calderwood

3 min read

Common VRF Issues Part II: Controls

By Walker Calderwood on Aug 20, 2020 10:00:00 AM

Topics: commissioning New Construction Controls upgrade design review

2 min read

Do Sweat the Small Stuff: Seemingly Small Issues Can Wreak Havoc in Buildings

By Walker Calderwood on Jun 19, 2019 10:00:00 AM

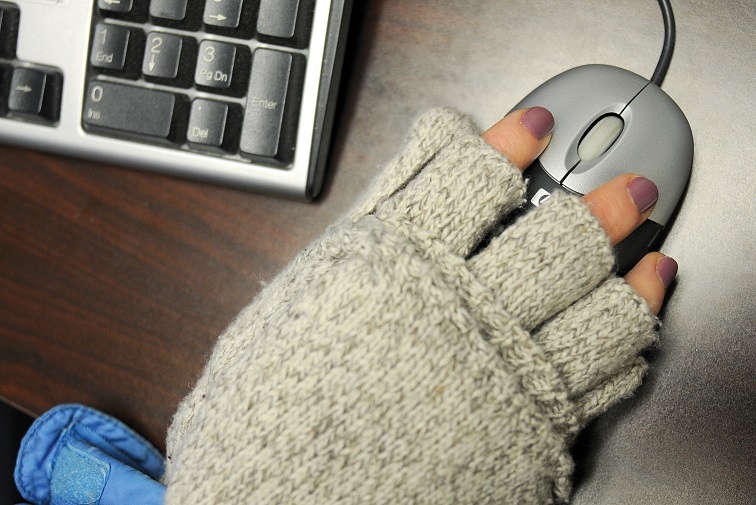

Sometimes certain parts of the commissioning and retrocommissioning process can seem trivial to both the contractor and the commissioning agent. Of course, the process involves some important and significant checks, such as ensuring the piping design detail matches the as-built piping, and that the specified ductwork sizes match the as-built ductwork size. But the commissioning process also deals with some of the finer details that may not seem as consequential or that have already been checked by multiple parties. So, why would the commissioning agent also need to check it again? In this post I am providing a couple examples of real-world commissioning issues that we’ve found. Each is an excellent reminder of why the seemingly minor commissioning verification steps are still required and important, even though they may seem inconsequential.

Topics: Building Performance & Technology retrocommissioning commissioning

4 min read

The Case for Monitoring Outside Air Flow in Hospitals

By Walker Calderwood on Mar 7, 2018 10:05:00 AM

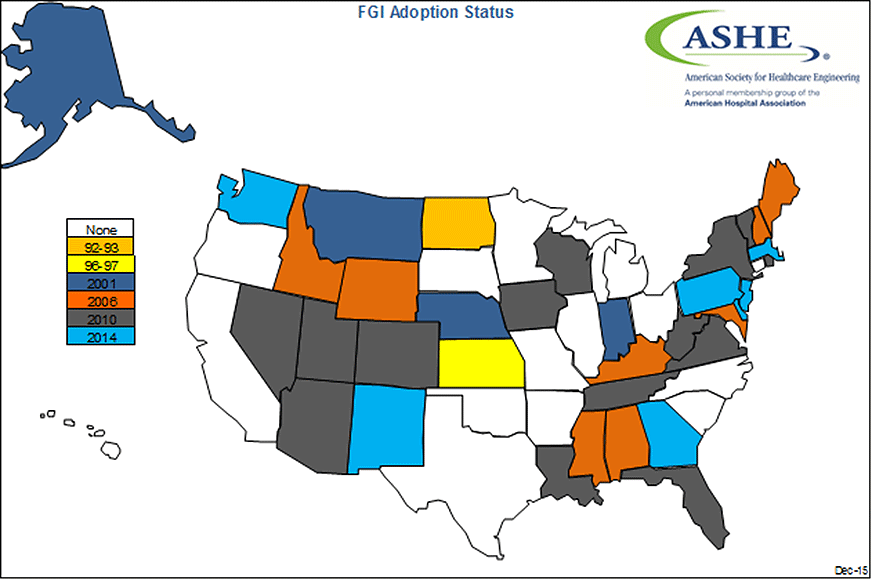

It can often be an afterthought as to how much outdoor air (OA) is actually being drawn into a hospital through air handling equipment, but maintaining proper outdoor air volume is a vital part of achieving effective infection control, as well as meeting space pressurization requirements. Proper OA volumes are also a metric that can be reviewed for non-compliance during Joint Commission audits. The amount of outside air that a hospital’s air handling equipment should introduce into the building is defined by the ASHRAE Standard 170, which was discussed in one of our previous blog posts, Optimizing Air Handling Units for Healthcare. As we pointed out in this prior post, an airflow station, when properly selected and installed, is an effective piece of hardware which can be used to monitor this outside air quantity (typically in cubic feet per minute), and the data provided by this meter can be very useful in a healthcare setting.

Topics: Workplace & People Building Performance & Technology

2 min read

How to Tell When It’s Time to Start The Retrocommissioning Process

By Walker Calderwood on Oct 4, 2017 10:00:00 AM

There have been many blog posts by Cx Associates’ staff on the benefits of retrocommissioning (RCx), or the best way to begin the RCx process, and even posts on how to increase RCx adoption through efficiency programs. All of these are great posts and I encourage reading them to gain a better knowledge of RCx. Even though many buildings can benefit from RCx, there are some buildings that are actually not good candidates for it. So how do you know if your building is a good candidate for RCx? In this post I am going to give some examples that building owners, operators, and occupants can use to identify whether their facility can benefit from RCx, and determine when it is time to start the RCx process.

Topics: Building Performance & Technology

3 min read

The Importance of Functional Performance Testing BAS Outputs

By Walker Calderwood on Jul 12, 2017 10:00:00 AM

Previous blog posts from my colleagues and I contain a detailed explanation of functional performance testing (FPT), an overview of how functional performance tests are created, and specific examples of how conducting FPT contributes to better building performance and energy savings. In this post I would like to expand upon the previous post “Functional Performance Testing Done Right: Details Matter.”

Topics: Building Cx & Design Review Energy Efficiency

3 min read

Optimizing Air Handling Units for Healthcare

By Walker Calderwood on Jan 11, 2017 10:00:00 AM

As I discussed in a previous post, “Optimizing Air Handling Units for Energy Savings or Improved Comfort,” energy savings can be realized by adjusting the amount of outside air that is introduced to an air handling unit during normal operation. In that article I referenced ASHRAE 62.1 to determine what the correct amount of outside air an air handling unit should mix with the return air stream. This same principle applies to air handlers in healthcare, and in many cases, there is an even greater opportunity for savings in healthcare applications.

Topics: Energy Efficiency Healthcare

3 min read

How Demand Limiting Can Help Control Energy Costs

By Walker Calderwood on Nov 23, 2016 10:00:00 AM

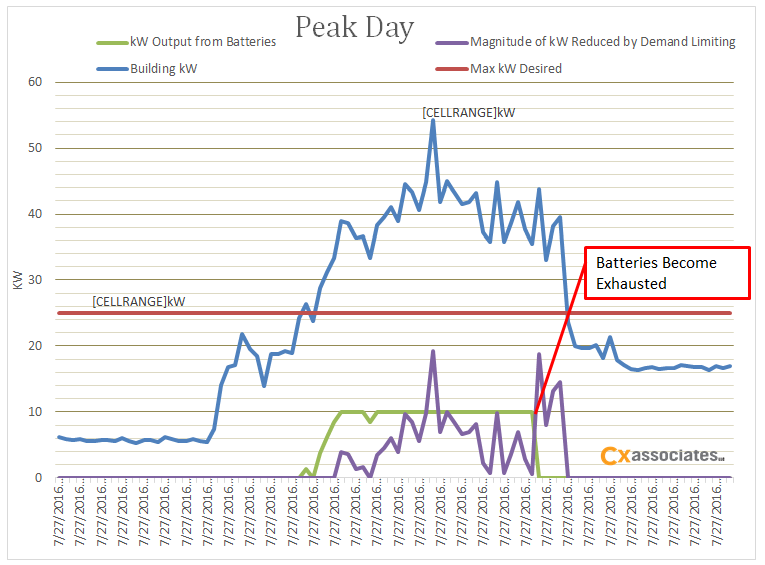

As a follow up to my previous blog post on peak shaving, this week I’m going to cover demand limiting. This is another peak shaving strategy that we are also using on the project I mentioned in my last post. Demand limiting is different than energy storage in that instead of using the same amount of energy from different sources than the grid to peak-shave, the amount of energy being used is limited to achieve the same peak shaving goal. I would like to note that there is no reason these two strategies can’t be used together - we are actually using both strategies on a current project to achieve the customer’s peak shaving goals.

Topics: Energy Efficiency

3 min read

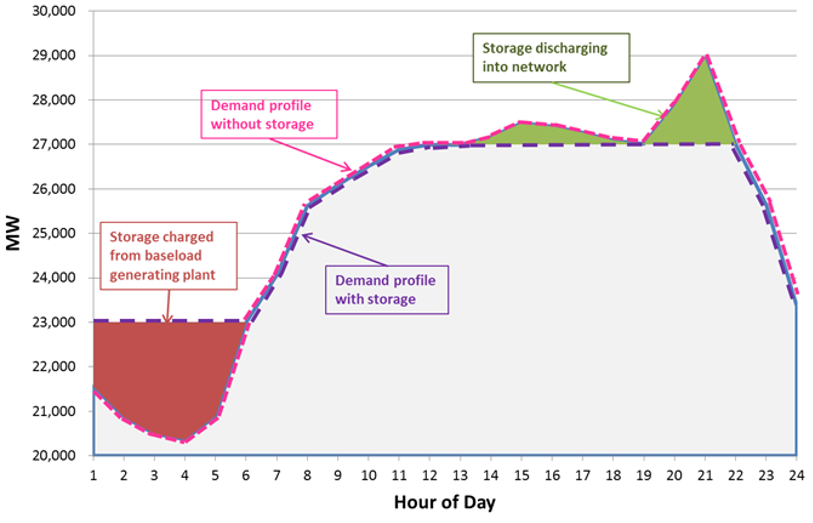

Peak Shaving To Save Money on Your Facility’s Electric Bill

By Walker Calderwood on Oct 7, 2016 9:30:00 AM

On a current project that Cx Associates is consulting on, the client has a goal of reducing their building’s peak demand charge. For commercial customers, peak demand charges are usually charged based on the peak kW demand of the building or facility during a certain time (e.g. 1-4 PM) of the day. If there is a peak kW outside of this specific time frame, there is no “peak demand charge” from the utility for this peak kW.

Topics: Building Performance & Technology

2 min read

Three Things to Check Before Deploying Energy Meters

By Walker Calderwood on Aug 24, 2016 10:00:00 AM

Metering equipment, such as light loggers, temperature loggers, and AC current loggers can be very useful tools and sometimes necessary in the world of energy efficiency consulting. They can provide useful data on how equipment is operating and performing. I have written about metering in previous blog posts including one called “EM&V Metering: Right Place, Right Time, Right Duration” where I described the importance of identifying the correct way of deploying meters. In this post I am going to discuss the importance of verifying that meters or loggers are working correctly even before a metering plan is developed or the devices are deployed, as well as the importance of ensuring that the correct sensors are chosen for the application.

Topics: Standards and Metrics Building Performance & Technology

2 min read

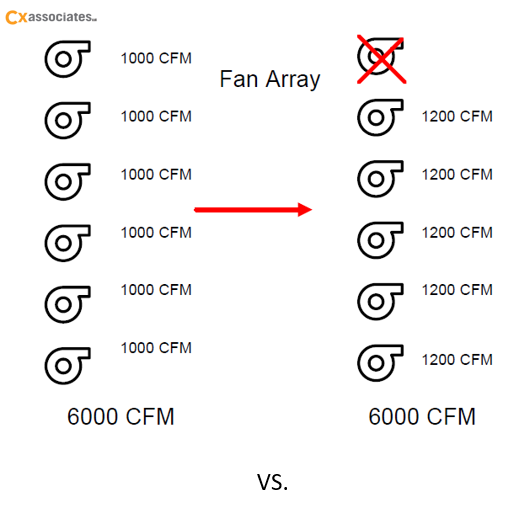

Using a Fan Array for Air Handler Redundancy

By Walker Calderwood on Jun 29, 2016 10:00:00 AM

On a recent project at a large hospital Cx Associates examined the feasibility of consolidating two air handlers into one single air handler. One of the air handlers is nearing the end of its useful life, and is the reason this project was brought to Cx Associates. While making an in-kind replacement was looked at, the replacement of this air handler presented an opportunity to replace another that was also aging, and located in a position that would be difficult to replace in the future. By combining the two air handlers into a single air handler there was an opportunity to essentially upgrade two air handlers at once at a lower cost than replacing them individually at different times. Maintenance advantages can also be realized by reducing the number of air handlers to maintain in the facility by one.