Previous blog posts from my colleagues and I contain a detailed explanation of functional performance testing (FPT), an overview of how functional performance tests are created, and specific examples of how conducting FPT contributes to better building performance and energy savings. In this post I would like to expand upon the previous post “Functional Performance Testing Done Right: Details Matter.”

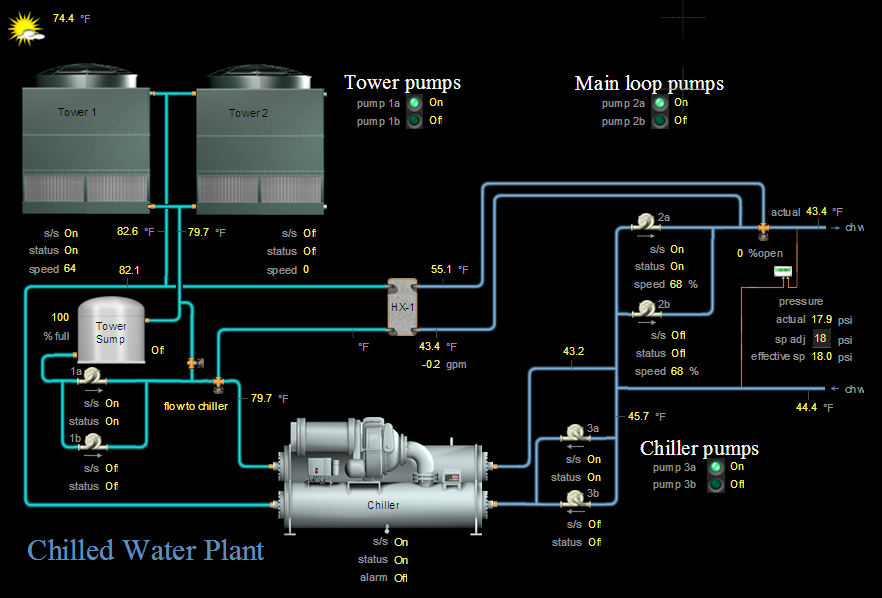

Modern building automation systems (BAS) are incredible tools that can provide an amazing amount of information in great detail that can give building operators easily digestible information on how their building is running. Where building automation systems can cause issues is when they are trusted too much, and what is on the screen is believed to be what is actually happening.

Katie’s example of carbon monoxide sensor calibration is a perfect illustration where a BAS can be misleading if not properly tested. In Katie’s example we learned about how an input to the BAS can be off, throwing off the results seen on the screen. But, the accuracy of the output of the BAS should also be verified as being accurate. Cx Associates engineers sometimes really “get into our work” – literally. Here you see our engineer Katie looking inside an AHU verifying the BAS outputs.

Here are a few examples of why BAS output verification is important:

- An outside air (OA) control damper is commanded to 50% open, and it says 50% on the BAS. But in reality, the OA control damper is 75% open because the control damper actuator slipped on the control damper shaft at some point. Without visually verifying the damper position no one would have known that the BAS was providing incorrect data. This is no fault of the BAS or the controls contractor, it is a situation that happened because a bolt came loose, and can be easily fixed. If this was never verified, the AHU would have been introducing an excessive amount of OA to the airstream causing the unit to use more energy than required and possibly impacting the heating and cooling performance.

- A heating coil 1/3 steam control valve is commanded to 0% open, but in reality, it is 100% open. Although it is shown at 0% on the BAS, if it was not visually verified, it may have never been uncovered. This is an example of a simultaneous heating and cooling situation as mentioned in Matt’s post. The cause of this situation was that the control actuator for the valve was accidentally set to a normally-closed setting instead of normally-open which caused the actuator to modulate in reverse of what the BAS was telling it to do. The resolution was just to change the setting on the actuator. A simple solution that helped prevent excessive energy usage and performance issues.

- A VFD is shown on the BAS operating at 60% (36 Hz) speed, but when the speed was visually verified on the VFD itself, it was actually operating at 50% (30 Hz). This is often due to a simple scaling error in the signal sent to the VFD from the BAS. Luckily, the bad information being generated at the BAS was an easy fix.

BAS output example

BAS output example

These examples further display how Cx Associates believes that functional testing is a very detail oriented process, and when the details are ignored, comfort and operational issues, as well as significant energy opportunities can be missed.