With the current COVID-19 global crisis, organizations all over the country are actively seeking ways to continue to provide the same level of services to their customers while keeping their employees safe. Cx Associates is known for its rigorous standards in the commissioning process, but a large portion of our work is contingent on our ability to be on construction sites, working with contractors to verify the installation and functionality of equipment. With Vermont’s order that all non-essential employees work from home, and with Cx Associates’ commitment to both keep our employees safe and prevent us from potentially spreading the virus on construction sites, we needed to quickly find a way to provide our on-site services remotely for the essential construction work that continues to move forward in a way that still matches our high standards. This blog discusses our approach to remote site work and how we're continuing to serve our clients while safely social distancing from our home offices.

Remote with the Help of CxAlloy

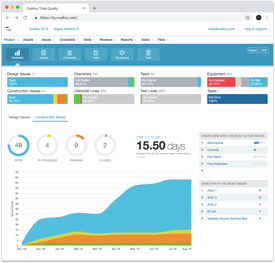

Photo courtesy of CxAlloy.com

Photo courtesy of CxAlloy.com

Before diving into the processes impacted by our temporary inability to do sitework, I first want to introduce CxAlloy, an online commissioning platform which has become our new standard for managing the paperwork and logs required by the commissioning process. This tool stores and tracks the design review log, issues log, prefunctional checkout documents, and functional testing documents. CxAlloy’s slogan “built for the field” couldn’t be more accurate. This tool allows us to review progress on our checklists and tests in real time, makes our onsite review more efficient, eliminates the need for paper copies, and has made it easier for the project team to fill out the documents and stay involved. I wrote a blog back in early 2014 when we first piloted CxAlloy, but so much has changed in 6 years! Now, most on-site foremen and project managers have iPads and are already working with online construction management platforms for drawings, RFIs, submittals, etc, meaning they have the tools needed to incorporate CxAlloy into their work flow. CxAlloy is a topic I hope to cover further in a future blog post, but for the purposes of this post, I hope to show how vital it has been in allowing us to complete remote site work during this unprecedented time.

Prefunctional Checkout

Prefunctional Checkout (PFC), a commissioning task which relies heavily on in-person sitework, initially presented itself as the more difficult undertaking to do remotely. PFC site visits tend to include some level of acrobatics - crawling around (sometimes inside) equipment, squeezing through tight areas, and attempting to put our eyes on all parts and pieces of sprawling systems. Prefunctional checksheets, which we provide for every piece of equipment and system on a job site, list out all the different components and details that we review when we are on-site related to equipment nameplate details, access, and installation. For each project, we post these PFC documents on CxAlloy, where the contractors can easily access and complete them prior to our verification.

In looking for solutions to remote PFC, we recognized that our checksheets alone hold a lot of important information that informs the direction of our site work. Without being able to go onsite, however, we needed a way to follow along on these checksheets and verify each line using the help of contractors as they complete the first pass of PFC. Luckily, CxAlloy makes it very easy to attach photos to a checksheet, and even to individual lines within a checksheet. So we redesigned our PFC documents to include very detailed photo requests that would allow us to verify each line of the checklist. For example, if we needed to verify that piping specialties (like a balance valve, control valve, strainer, etc.) for a heat pump were installed according to the design drawings, we’d ask for a photo of the piping that included these specialties and showed the heat pump in the background so that we could identify supply versus return piping. Our goal in this version of PFC was to add little extra effort on the contractor’s part, as they fill out checksheets first anyway. After the PFCs are completed by the contractor and the pictures uploaded, we can then spend time reviewing the submitted photos and notes, looking through each photo for all of the different items we’d check if we were onsite. Through this process, we can accomplish a very thorough review of the equipment and installation from home. Any items or questions that may need further follow-up or review can be done with the team over conference call, the same way we would meet with contractors on site with any questions or follow up.

We recently completed this process for a project with installed heat pumps and associated piping and ductwork. Overall, it went very well. The biggest obstacle we encountered was that not all photos included every aspect of what we wanted to see, either due to the angle of the photo or the placement of the equipment. This has re-emphasized the importance in ensuring we are clear and specific in our explanations of what we are looking for in each photo. We also recognize the huge importance that cooperation and collaboration with the contractors makes for successfully completing this process remotely. Without their willingness to work with us and be a little flexible with their time, we wouldn’t have had the success that we did. We plan to use this approach on several more projects that are getting close to needing on-site PFC work while we continue to work from home and hope to hone the process to make it easier for contractors and for us.

Functional Performance Testing

Functional Performance Testing (FPT) is a commissioning task that happens toward the end of the project and tests the HVAC controls to verify that equipment is running as intended. FPT usually requires many hours on site, working closely with the controls contractor to walk through testing sequences. Because most of our projects use internet-accessible building automation systems, this process is slightly easier for us to do remotely compared to PFC. Although there are still aspects of FPT that we won’t be able to complete remotely and will need to wait until we can safely be on-site (sensor calibration, verifying temperatures, verifying pressure relationships, etc.), there is a LOT we can check from the safety of our home offices. By having remote access to the controls system and/or screen-sharing with an on-site controls contractor, we can confirm that all sequences have been implemented per the design, verify accuracy of the graphics, and test all safeties and alarms. We can also use trend data if it’s available to confirm sequences and flag any potential issues in how the systems are functioning. Completing as much FPT as possible before the building is occupied ensures that the building operators receive systems that work as expected and will receive alarm notifications when there are failures or conditions that can impact the longevity of the equipment.

What’s Next

With the uncertainty of how long the COVID-19 crisis will last, Cx Associates will continue to work diligently to ensure our on-site processes can be completed remotely with the same level of detail we typically provide. In addition to the approaches mentioned above, we are also working on setting up a body camera with a built-in cellular network that we can send onsite for video footage of installation. We hope that through our efforts and by working closely with the construction teams that continue to be deemed essential, we can provide the level of service our clients have come to expect while doing our part to flatten the curve.