In my last blog post, I discussed the short- to medium-term hiring of an Energy Auditor. But if your firm is dedicated to energy efficiency as a matter of doing business, you are looking for a person to act in a long-term role of an Energy Manager. This position doesn't have to be full-time and it can be held by an outside consultant, but you want someone who will learn your facility, your equipment, your employees’ needs and your process needs. This can’t be a tactical strike as the energy audit is, because an audit is only a snapshot. If energy management is a goal, you need someone who will stay with your business and keep abreast of the changing needs and circumstances. This takes a high level, managerial decision to invest in the efficiency of the facility.

Facilities Manager: Conductor of the Orchestra

A Facilities Manager is, as the name applies, responsible for the entire facility. This person ultimately oversees everything from the replacement of burned out light bulbs, to the security of the building, to the spills on the floors, and to the functionality of the building equipment. Facilities staff must respond to every comfort complaint, every process equipment malfunction, and every alarm while staying within budget. Needless to say, facilities staff are very often stretched thin and are often in reaction mode!

Photo by Elliot Margolies

Photo by Elliot MargoliesSome Facilities Managers may have the time to devote to energy management, but most hire this job out so that someone can commit to the focus it requires.

Energy Manager: Dedicated Position

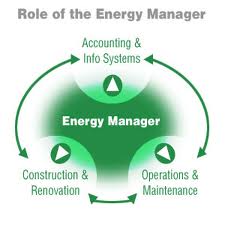

That leads me to the Energy Manager. This role is responsible for identifying energy efficiency opportunities, providing a cost and savings estimate so that the project can be debated and prioritized, overseeing the implementation of the opportunities and documenting the savings after implementation. This person can be a consultant that works a certain number of hours per week at your facility, it can become a portion of a current employee’s job description, or it can be a new full-time position. It should be a person with energy management credentials such as a Certified Energy Auditor (CEA) or Professional Engineer. Many companies incorporate this position in the Facilities department, but it can also report directly to the CEO or CFO. Depending on your company’s structure, it needs to fit where it will have the ear of the people who can make things happen.

Warning - Change Is Never Easy

A few words of caution: an Energy Manager will bring ideas to the table that may upset the status quo of the current structure. When an Energy Management position is created (even if it’s internal), staff (whether in Facilities, management or process) can get defensive. Efficiency opportunities may put people on the spot as to why they haven’t identified this necessary improvement before.

US Navy 110809-N-HC601-002 Faye Sherbert, left, a facilities manager for the U.S. Naval Supply Systems Command, Fleet Logistics Center (FISC) San D (Photo credit: Wikipedia)

US Navy 110809-N-HC601-002 Faye Sherbert, left, a facilities manager for the U.S. Naval Supply Systems Command, Fleet Logistics Center (FISC) San D (Photo credit: Wikipedia)In addition, if the people who can make things happen do not also have a professional goal of saving energy, then this position can be undermined and potentially ineffective. As mentioned, a Facilities Manager is responsible for so many parts of the plant operation that they are often focused solely on keeping the business running with minimal complaints and issues. Unless energy savings is part of their goals, there is little incentive to upset the apple cart with changes. We have experienced working as an Energy Manager reporting to the CEO, where the Facilities Manager was not responsible for energy reduction. Until it became part of the Facilities objectives, the implemented energy improvements were small. When these goals were included in their job descriptions, the Facilities department became engaged and willing to examine new ideas.

Of course it takes checks and balances – we certainly can’t implement good energy savings measures at the expense of the company’s product quality. It takes a team of people to determine the validity of an improvement. Process staff need to make sure the change will not adversely affect the product; Facilities staff need to ensure the employee safety and comfort are maintained; and the financial staff need to ensure the economics of the project fits within company budgets. Everyone needs to be cautious; they are the ones who get the wrath when things go wrong!