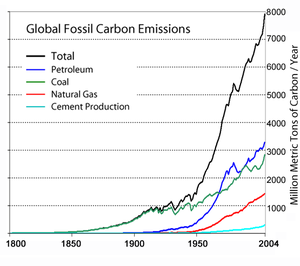

Desalination is an expensive and energy-intensive way to produce fresh water, but for some areas of the world, it is the only available option to support growing populations or to mitigate effects of degrading water resources. Are there opportunities to meet this demand for fresh water in a more energy efficient and cost-effective way?

The Desalination Process

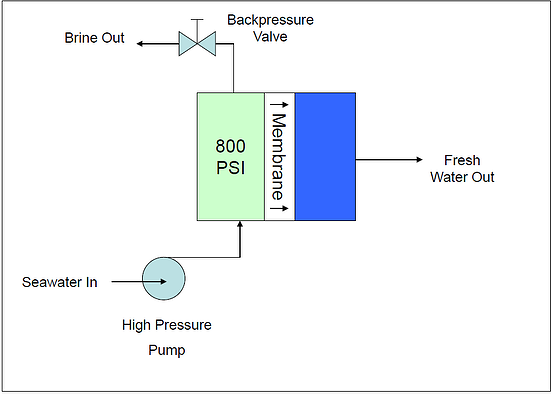

The most common method for seawater desalination for more than 30 years has been reverse osmosis (RO). The technology boils down to essentially pumping seawater at high pressure against one side of a semipermeable membrane, which only allows water molecules to pass through it. As the fresh water passes through the membrane, the salt remains behind creating a salty brine which has to be discarded and constantly replenished with fresh seawater. Systems typically require 3-5 times more seawater to be pumped than fresh water produced.

To operate seawater reverse osmosis efficiently, in addition to providing a continuously refreshed supply of seawater, the seawater must be supplied at very high pressures. The osmotic process does not reverse until pressure reaches around 400 PSI across the membrane (for seawater). To have meaningful production of fresh water, the pressure needs to be twice as great--800 PSI--for most systems.

Opportunities to Improve Energy Efficiency

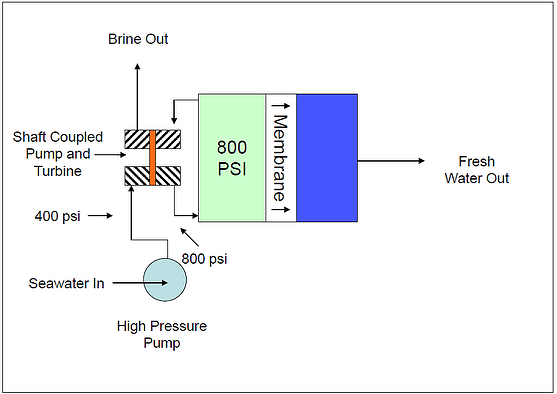

RO membrane efficiencies have improved over the years, leading to some reductions in RO energy use. There are also energy recovery technologies available which can significantly reduce the energy requirements for seawater RO—some by as much as 75%. There are several different approaches used, but they each recover some of the energy which is leaving (and being wasted) in the leaving brine stream at the end of the process. Traditionally, the brine stream leaving the unit has a backpressure applied by a throttling valve (see figure 1, above) in order to maintain the required pressures in the RO. Instead of using a throttling valve, by providing back pressure to the brine stream with, for example, a turbine, some energy can be recovered and put back into the seawater pumping process thereby reducing the electrical loads on the pumps. In this example (the energy recovery turbine) the brine stream is run through a turbine which rotates. The turbine is connected by a shaft to a booster pump which does some of the work required to pressurize the seawater coming into the system—reducing the loads on the high pressure pump, and associated energy use. The schematic in figure 2, below, illustrates this approach.

Another approach to energy recovery is a rotary pressure exchanger. Energy recovery technologies can reduce the energy requirements to less than 1.6 kWh per cubic meter—which is definitely an improvement over early systems.

Cost-Effectiveness is the Key

The bottom line, however, is that desalination through the best available technology is still very energy intensive—and as is the case for efficiency on the electric side: reducing demand is nearly always more economical than adding capacity.