A friend of mine recently sent me an article from the Automatedbuildings.com online magazine entitled “Death of the Controls Industry” written by Therese Sullivan (Principal of Building Context Ltd). The article contains summary of a presentation given by Darren Wright, Director at Arup. Darren Wright makes the case that we have a major problem in the building energy market, and it’s directly attributable to the controls business model still not being open source.

Mr. Wright is Right On

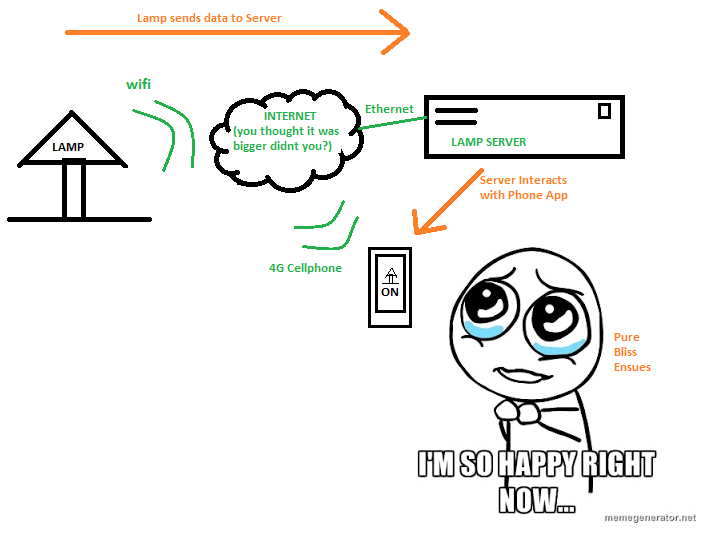

Darren Wright’s presentation is spot on. Not only is it well put together, easy to watch and understand, and well delivered, but it is also showing that this industry is about to change. That it must change. We are walking into a new world with a new technological approach to networked devices, and we call that the “Internet of things” (IOT). This new buzzword represents the ability for any daily use object (let’s say a desk lamp), to receive an embedded controller with a wireless network interface, and voila – this desk lamp is now online and able to be controlled over the internet via something like your smartphone or desktop computer.

I share his perspective on the fact that there are no open source (or even open system) controls products out there, but this industry requires it. I can also see where the IOT is a potential leveraging technology to gain access to smarter data. However, the problem I see with using an IOT-like technology in the commercial industrial building space is getting people to let their systems be cloud-dependent.

Open Source

Mr. Wright calls for open source because our industry calls for it, whether or not it knows it yet. I am not sure who his audience was but I hope it was building owners, and construction managers. The people with the purse strings really need to understand that they’re not getting systems where anybody can come in and work on them. For example, if I were a mechanical contractor who was bidding on a job where I sell AHUs, pump, ducts and piping that only my company can service, I would never get the job. All these components are installed to a standard controlled outside of any one manufacturer, therefore they are an open architecture. If this example is not terribly clear, let me point you to a cool video that explains it in different terms, LEGO!:

This video is great because they really illustrate some good examples on the following benefits of open source:

- Access to the source

- Free remix and redistribution

- End to predatory vendor lock-in

- High Degree of Cooperation

None of these currently exist in the BAS controls industry. Independent controls vendors (those that are self-owned and rep one or more controls products) do sometimes allow the building owners access to the programming within their controllers, but usually at a cost. They do this because they too want to be open for their customers because they recognize the value in open systems, but they’re generally bound by the rules and prices attached to the products they resell.

Since traditionally controls vendors make money for every change to your system, they very often balk at the idea of a building owner having access to the source. Controls vendors may assume that an owner who wants access to the source means that the owner might be modifying his or her own system, removing that revenue stream. Not allowing access to the source can potentially be a missed business opportunity for the controls vendor. While there are the a-typical vendors who do enable their customers to take control over their buildings, they are not the norm.

The term Predatory Vendor Lock in sounds awful. I’ve never met any controls person (save one, there is always one, am I right?) who have intentionally tried to do this. However, vendor lock in still occurs because, in most cases, should programming changes be required, the building owner must return to the same company that installed the controls in the first place to get these changes to occur. Why can’t they go to Company B you might ask? This is because the industry is setup on manufacturer-imposed sales territories which enforce predatory vendor lock in. Company A and Company B in the local market will rarely sell the same controls products as the manufacturers won’t allow it. Due to the lack of a common controls programming language across products, this means that you’re stuck with Company A unless you take matters into your own hands. Therefore there are no market-based competitive forces for Company A to do better than Company B beyond low bidding during new construction. It’s a problem with the industry, generally not the independent local controls folks. Most local controls folks would like this changed too so they can sell their company on having the best service, and the smartest team. Good service and team smarts are the core of any local controls contractor after all. A truly open source platform would allow Company A, the company with the best service and smartest team, to take over a building from an under-performing Company B with very little (if any) upfront cost to the building owner.

A high degree of cooperation is hard to achieve in any competitive market. This is changing in our industry as there is an increased number of existing buildings with control systems that are ripe for retrocommissioning. As consulting engineering firms become more computer savvy, they too want to dive deeper into the controls programming in order to optimize systems for increased efficiency and performance. With an open system, this could become a more efficient process with analytical tools to expedite controls sequence changes that would yield energy savings. This efficiency would come from a single learning curve from the singular open source programming language this concept requires.

Hear the Call

We need an independently developed and non-profit based standard open source controls solution to level the playing field for building owners. This will enable both building owners and independent controls contractors to come together in a more cooperative and market enabled way to ensure that the buildings they work on are energy efficient and open. It will also enable the engineering community to learn a single method of providing logic upgrades and best in class sequences to both controls contractors and building owners through retrocommissioning. Everybody wins in an open controls world, we just have to hear the call and continue to push for our industry to adopt this change.