Lighting control systems are making their way into new construction and are becoming as common place as HVAC controls. Just like with many new building technologies, lighting control systems started small, and are now gaining more and more market penetration. This is great news for those of us who work towards saving energy for building owners. This new frontier of controls creates new challenges for those of us who work towards saving energy for building owners. Why, you ask?

A Controls Engineer’s Perspective

I’ve been working with HVAC control systems since 2002. I witnessed the dawn of “vendor interoperability” (commonly mislabeled “open systems”), the adoption of the LONworks protocol, and then the BACnet protocol as prevailing industry communications standards. Both protocols are a means of modeling system data. In HVAC you need to model temperatures, pressures, equipment states, modes of operation, schedules, etc. The list can be quite lengthy, because HVAC controls potentially have a lot of integration options across potentially many pieces of equipment. So, these protocols are a means of conveying, via common understood digital mediums, information the system gathers and controls.

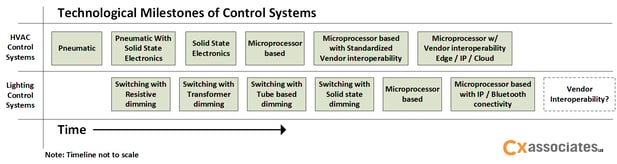

The HVAC industry didn’t arrive at this easily. In the 1990s HVAC control systems were exploding on the scene with digitized controls. What I mean by this is that control systems were becoming microprocessor-based. Prior to microprocessor capabilities, we had solid state electronic systems (systems without a processor, but still electrically driven) that were essentially electric circuitry designed to mimic the behavior of pneumatic system. These systems were not reprogrammable – they took an electrical input and generated an electrical output based on their application specific function.

Until relatively recently in most commercial buildings, the pneumatic/solid state era is where lighting control systems existed for a very long time. In the lighting realm, relays, potentiometers, auto-transformer dimmers, and single function electrical devices have been the primary means of lighting control for decades. Sure, the way we have switched and transformed the driving current of florescent and incandescent bulbs has found efficiency gains over the years, but the sophistication of advanced lighting control systems has only recently expanded (from industries like theatre into the commercial building market) opening many doors of potential to the industry.

Currently, the state of lighting control systems is at a point that feels very much like the HVAC controls industry in the late 90s. They are still establishing their data models (on/off, dimming, scheduling, etc.). They have lots of new programmability, software, feature sets, and networking options, but they do not have industry standard protocols like LONWorks or BACnet. Some of them have adopted BACnet (which I, being biased of course, encourage and support) as their means of interoperability. Other standards like nLight and DALI are still testing the market trying to establish dominance. One thing is for certain, just like in the HVAC controls industry, one standard will eventually become the standard. Only time will tell.

The Devil is In the Driver Details

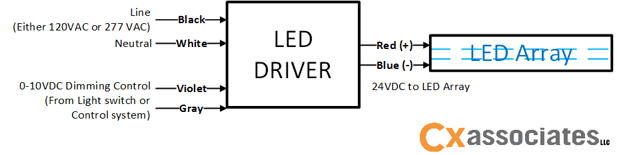

Regardless of the communication and wiring standards for control interoperability across products, there are other areas for improvement in the lighting industry that we should recognize. Recently I did a project where I learned that LED lighting fixture submittals do not contain any information about the LED driver used by the fixture. This surprised me as the LED Driver is the functional component of the light that allows us to use LEDs. Apparently, this is pretty par for the course as the function of an LED driver is pretty simple. It drops the supply voltage (typically 277 volts alternating current) down to a UL rated class 2 voltage (typically 24 volts direct current) to power the LED array in the fixture and it also provides a means of dimming that LED array. Most contemporary LED fixtures are dimmable and this is great opportunity for energy efficiency as LED dimming techniques almost always reduce the power consumed by the fixture due to LEDs being solid state and direct current devices.

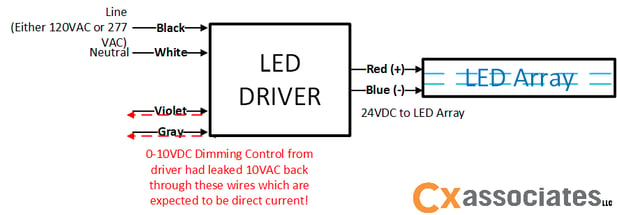

So, what was the problem with not providing information about the driver with the fixture submittal? During a recent project, we had installed fixtures that were leaking AC voltage through their drivers onto the 0 – 10v DC input wires used to dim the fixture.

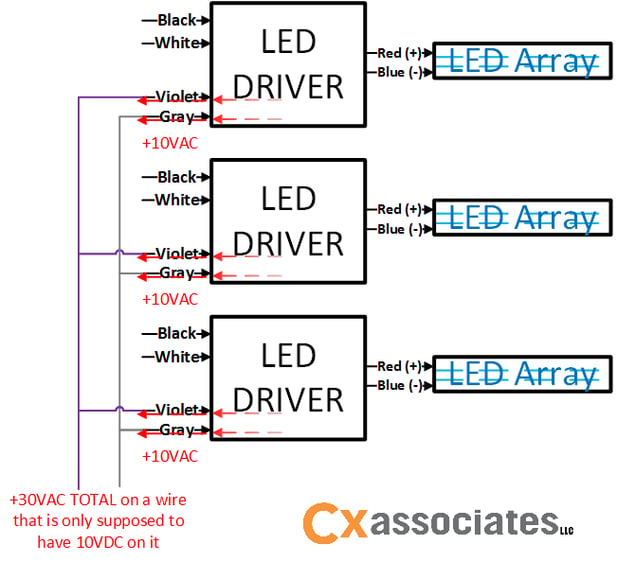

This AC voltage leak was cumulative (in that the more fixtures added to the same dimming zone, the more AC voltage leaked onto the dimming wires). So as more fixtures were added, the wires exceeded the 10 volts DC maximum everyone was expecting to measure on those wires.

Some folks who are familiar with the industry might say: “well they didn’t get isolated drivers.” To them I would reply that the cut sheet on the driver that was leaking AC voltage indicated that the driver was indeed isolated. Drivers listed as “isolated drivers” are meant to isolate the AC side of the fixture from the DC side of the fixture. So, we had an “isolated diver” that wasn’t performing in isolation – on more than 30 fixtures.

It turns out that when fixtures are submitted for projects, the lighting manufacturer doesn’t have to provide an indication of what LED driver will come packed inside the LED fixture. In interviewing some lighting reps at the Better Buildings by Design conference this year, I was told that this is because lighting fixture manufacturers may change LED drivers on the fly for any given fixture. This is because of supply and demand in terms of driver manufacturers and their respective stock of drivers. If a fixture manufacturer runs out of driver stock, they’re going to shop for an “equivalent” driver if they can’t replace their stock with the one they were using. There are probably more reasons for this depending on who you ask, but this was the nutshell-answer I came away with. I find this to be a big problem in the industry because the most complex component of these lights is allowed to be inconsistent. There is no way to review this component ahead of purchase, and you never know what you’re going to end up with as a result. This can be avoided if the lighting fixture vendors included the make and model of the driver they are packaging with each fixture.

A Bright Future

Just like HVAC controls, I hope the lighting controls market will settle out on one or two non-proprietary communication protocols that are manufacturer-independent. It would also be nice to see lighting controls sequences be part of electrical drawings in contract documents. To those of you in the business of making lights I highly urge you check out ASHRAE Standard 135 (BACnet). I also would love to see a push for manufactures to include driver cut sheets as part of a fixture submittal. Or, change their part numbering systems to allow vendors to choose the quality of their LED drivers based on project specifications, even if it means spending more money. There is a lot of room for growth in this industry and I can’t wait to see what innovations are on the horizon.