Commercial and industrial businesses spend a great percentage of their building costs on creating hot and cold water and pumping it around their facility. This infrastructure includes chillers, boilers, cooling towers, and pumps used for heating, cooling, process cooling, and domestic hot water. Considering how much money is spent on this portion of the business, it is not surprising that there is an increased focus on determining the correct amount of water required to meet the needs of the business. This blog post aims to explain the differences between the various flow meters currently on the market.

Traditional Pumping Design: Safe but Expensive

Traditionally buildings had constant flow water loops that used a bypass to divert water back to the conditioning source (chiller, cooling tower, boiler, hot water heater) when the end uses (air conditioning units, terminal heating units, process equipment, bathrooms) do not call for water. A bypass ensures the conditioning sources and pumps do not experience a low-flow situation that can cause serious mechanical damage. Although effective in meeting the needs of the building and equipment, this constant flow design requires a lot of unnecessary water flow, decreases the life of the equipment, and adversely affects energy costs.

Variable Speed is the Answer

More recently, building systems use variable speed equipment and pumps to vary the system’s flow. This matches the water flow (gallons per minute) to the needs of the building, without wasting energy and reduces the wear on the equipment.

Flow Meter Types for Monitoring

To monitor the flow of the systems, there are electromagnetic and ultrasonic type flow meters that can be of insertion, inline, or clamp-on design. An electromagnetic flow meter applies a magnetic field which results in a potential difference proportional to the flow velocity perpendicular to the flux lines. The physical principle at work is electromagnetic induction. An ultrasonic flow meter employs the frequency shift (Doppler Effect) of an ultrasonic signal when it is reflected by suspended particles or gas bubbles (discontinuities) in motion. This metering technique utilizes the physical phenomenon of a sound wave. The meters output information on total flow (gallons), flow rate (gallons per minute), and alarm conditions. With this information, you can tailor the system to match the water flow to the building demands. This is typically done through a BMS, but can also be done on smaller buildings that do not have a BMS.

Insertion Type Electromagnetic Flow Meters

The insertion type flow meter consists of a probe with an electromagnetic sensing head that is inserted into the center of a pipe – pipe size is not limited.

The advantage to an insertion type meter is that the unit itself is more economical than an inline type meter and the installation is considerably easier. The insertion probe can be installed using a hot tap fit without requiring the interruption of water flow. The disadvantage is the long required straight pipe: 50 times the diameter of pipe upstream of the meter and 5 times the diameter of the pipe downstream of the meter. In addition, the accuracy is approximately ±2%, which is double that of an inline meter.

Inline Electromagnetic Flow Meters

An inline electromagnet flow meter is installed in the pipe itself, with a flanged or threaded connection. Its accuracy is traditionally around ±1% and requires a straight pipe run of 3 times the pipe diameter upstream of the meter and 2 times the pipe diameter downstream of the meter. This enables considerably more opportunity for installation than an insertion type meter. The drawbacks of an inline meter are its price and that a water system must be shut down for its installation.

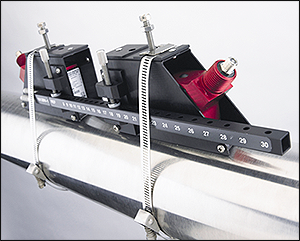

Ultrasonic Flow Meters

An ultrasonic flow meter uses ultrasound waves to calculate the flow of water through a pipe. There are inline versions for small (up to 2” diameter) pipe and clamp-on type for larger pipes. A clamp-on design is also useful for temporary metering or for situations when interrupting flow for meter installation is not permissible. Our firm uses this type of meter for retrocommissioning analyses and in our evaluation work. The advantages are that the same meter applies to all pipe sizes, water flow is not interrupted, and the accuracy is quite good (depending on manufacturer). The recommended length of straight pipe is 10 times the pipe diameter upstream of the meter and 5 times the diameter downstream of the meter. As ultrasonic waves rely on the reflecting off of particles or bubbles in the water, this type of sensor is not applicable to distilled or drinking water systems.

Understanding Flow Meters

Are you interested in learning more about metering your facility's water usage? Get in touch with us!