Recently I wrote a Building Management System (BMS) controls specification for a customer who needed a controls upgrade. It was an excellent opportunity for me to flex a new engineering perspective and see what energy savings I could squeeze out by retrofitting an existing mechanical system with a new control system. When it came to the sequence of operations, I decided to consult ASHRAE Guideline 36.

What is ASHRAE Guideline 36?

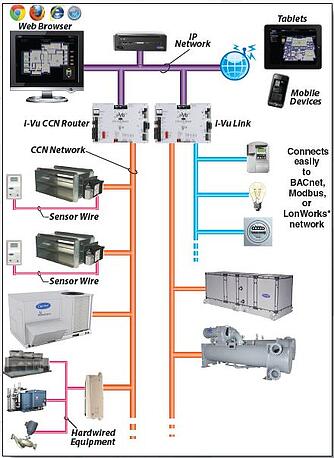

ASHRAE Guideline 36 (which is currently in "advisory public review draft" and not yet finalized) was created as a means to put out “best-of-class” control sequences that will make adhering to other standards ASHRAE maintains easier. It’s meant to be used in systems that contain modern day equipment (such as variable frequency drives [VFDs]) and fully programmable control systems. It will be distributed to manufacturers of control systems as well as the general ASHRAE community. In short, it gives you the gold plated “Cadillac” control sequences that will yield a highly energy efficient building using a high degree of complexity.

Initial Impression

This thing is awesome! I saw a lot of great new concepts that I’ve never considered before. I was also happy to see features that I’ve previously implemented to help control systems be as “smart” as possible. There are a lot of common sense items that are spelled out in the guideline that not every automatic temperature controls (ATC) contractor sees eye to eye on. For example, it specifies that all deadband and tuning parameters are to be adjustable and all input/output points are to be overridable. I think both those ideas are great. Where it falls short is that it does not adequately take into account the current state of the market. Let me explain ...

Our Current State of Affairs

Today I see facilities of all shapes and sizes for a multitude of organizations and businesses each with a different mission and differing budgets. Market forces currently drive ATC contractors to provide rock bottom pricing, which incentivizes bare minimum systems (most of the time). If ATC contractors were to estimate a fully Guideline 36-compliant control system’s price tag, their prospective clients might choke. The price tag would be higher than current market prices allow because controls contractors are not implementing even a minority of the programmatic concepts of ASHRAE Guideline 36 (yet). The degree of complexity is way higher than the current standard industry expectation.

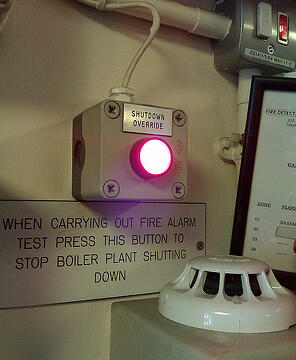

I also see another issue that’s related to minimum pricing: the owner who has to live with the system. Many facilities try to stretch their maintenance budgets and rarely spend the money they should on highly trained staff and on maintaining their building systems. There are definitely exceptions to that, but they’re few and far between. Therefore the staff hired to operate these building management systems can be easily overwhelmed by complicated feature sets that are energy efficient. As a result, operators who lack training and expertise in this area may issue overrides, disconnect equipment, and begin manually operating the system. Energy efficiency goes out the window, almost literally.

A Post-Guideline 36 World

While I understand Guideline 36 is meant to be the cream of the crop, I cannot wait for it to generally become the norm. I can envision that Guideline 36 becomes adopted by most controls manufacturers. I imagine many manufacturers would create what we call “canned programs” around Guideline 36. I can also imagine that they would allow their distribution network of ATC contractors a means of selecting the features in Guideline 36 (much like you select features for a car online) based on the specifications they’re given. This future controls manufacturer would then be enabling their distribution chain the ability to offer rock bottom pricing on Guideline 36 compliant systems. But the problem of insufficient training may still remain for facilities folks. That’s where consulting engineers could come in! I can also imagine a day when we give affordable training to make understanding Guideline 36 sequences easier. If you would like some advice or help with implementing Guideline 36 sequences, please feel free to reach out. We’d be pleased to talk to you about it.