You might have heard of Maslow’s hammer, that old adage “I suppose it is tempting, if the only tool you have is a hammer, to treat everything as if it were a nail.” In my experience I’ve seen the practice of outside air temperature (OAT) reset, which is shorthand for a method by which building systems are “primed” to deal with real-time outdoor air conditions, treated as that hammer. I’ve found it in the common sequence of operations (building technology speak for the computer programs which make building systems operate) designed to control everything from supply air temperature from a VAV box, to resetting the valve positions on fin tube radiation zones.

OAT Reset in a nutshell

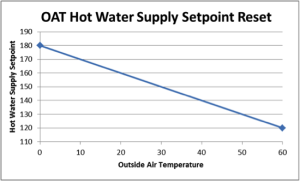

Sometimes you have a nail, so a hammer is the right tool. OAT reset is great for representing a “proxy” to the buildings internal heating demands reacting to seasonal change. Generally we see it used to reset hot water supply (HWS) set points for hydronic heating systems (for your boiler at home, or in the office). It generally goes something like

Sometimes you have a nail, so a hammer is the right tool. OAT reset is great for representing a “proxy” to the buildings internal heating demands reacting to seasonal change. Generally we see it used to reset hot water supply (HWS) set points for hydronic heating systems (for your boiler at home, or in the office). It generally goes something like

- If your OAT = 60°F, then HWS shall be 120°F.

- If your OAT = 0°F, then HWS shall be 180°F.

This is a very common copy/paste sequence for heating systems (it even comes as a standard feature on many modern residential boilers) and it is highly effective at keeping the building comfortable, while saving substantial energy when outdoor conditions are milder. It assumes (quite correctly) that you’re going to need more heat as it gets colder out. The reason it works so well for hot water systems is that these system have one function—deliver heat to equipment that demands it. If there is no demand for heat somewhere in the building, the reset has no impact on the spaces.

OAT Reset Misapplied

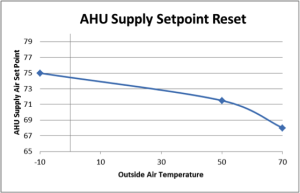

Where I see the most common application of the hammer when you really need a wrench is Air Handler Unit (AHU) Supply Air Temperature (SAT) reset. This type of OAT reset is a poor fit for this application, and it results in a blunt force reaction to a problem that you may or may not have (poor building envelope). The Sequence generally goes something like this:

Where I see the most common application of the hammer when you really need a wrench is Air Handler Unit (AHU) Supply Air Temperature (SAT) reset. This type of OAT reset is a poor fit for this application, and it results in a blunt force reaction to a problem that you may or may not have (poor building envelope). The Sequence generally goes something like this:

- If your OAT = -10°F, then AHU Supply shall be 75°F.

- If your OAT = 50°F, then AHU Supply shall be 72°F.

- If your OAT = 70°F then AHU Supply shall be 68°F.

Applying OAT Reset to an AHU should really be a last resort (which in my opinion should reek of desperation!). Where I’ve often seen this sequence is in fully BAS-controlled buildings with a plethora of BAS points at the disposal of the building’s design team, which could have been used as a better proxy for the building’s needs.

I get it, simply using OAT reset will work, and will probably minimize complaints, but it fails to respond to the demand of the building directly. To better meet those demands, why not use a point, in place of OAT, that directly measures the building demand? These points might be return air temperature (RAT), or better yet, use a survey of the space temperatures already being logged by the BAS.

Drop the Hammer

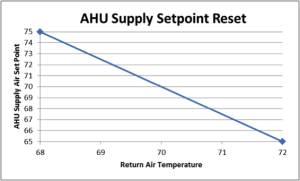

Let’s consider air handler return air temperature (RAT) in the place of OAT. You would start by calling for the range of RAT to the temperature range allowable in the spaces. So now you have something that looks like this (let’s assume it’s an office):

Let’s consider air handler return air temperature (RAT) in the place of OAT. You would start by calling for the range of RAT to the temperature range allowable in the spaces. So now you have something that looks like this (let’s assume it’s an office):

- If your RAT = 68°F (the coldest you’d like to your spaces to be), then AHU Supply shall be 75°F.

- If your RAT = 72°F (conversely the warmest…), then AHU Supply shall be 65°F.

See the Results

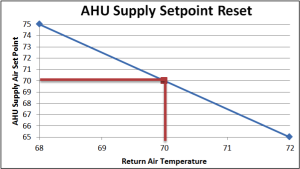

If you reset the supply air to slightly outside the same range you’d like your space to be, you’ll end up with the unit delivering heating/cooling proportionally (assuming your supply air control can deliver air at setpoint properly) to the majority demand of the spaces served by the AHU. The system naturally becomes a democracy!

Furthermore, when your space is about 70 degrees (a good neutral room temperature), you’ll be delivering neutral air. This is important. You should always try to center the reset range on the ideal condition in the spaces, or space setpoint so that at that temperature, the air delivered by the AHU is neutral to the spaces so as not to influence the spaces in one direction or another. Let the reheat boxes and/or perimeter radiation provide heat on an individual basis, and when the majority of the spaces call for cooling (as OAT rises) the system will respond accordingly.

This allows the OAT influence on the spaces to act on an individual basis (as allowed by building envelope). So what if all your perimeter rooms, during winter months, will call for heat. Unless they’re the majority of spaces served by the unit, they’ll use their local Fin tube or reheats to handle that OAT influence without causing the internal spaces (less affected by OAT) to artificially overheat.

The beauty here is OAT will still influence the behavior of the unit (as it does with the traditional reset) but it has to do so through the building’s envelope. This means buildings with a poorer envelope will have majority calls for heating from all the zones, so the AHU will respond accordingly. In situations where OAT may only influence a minority of zones (say a unit serving majority non-perimeter spaces) the unit won’t prematurely react at the expense of your gas bill.

The beauty here is OAT will still influence the behavior of the unit (as it does with the traditional reset) but it has to do so through the building’s envelope. This means buildings with a poorer envelope will have majority calls for heating from all the zones, so the AHU will respond accordingly. In situations where OAT may only influence a minority of zones (say a unit serving majority non-perimeter spaces) the unit won’t prematurely react at the expense of your gas bill.

If you want to take this even further, there are a few more ways to refine this concept and make it a slam dunk energy saver. If you’re interested in hearing about it, feel free to reach out to us.

Related posts:

Getting the Most Out of Your Commercial Condensing Boiler

Big Energy Savings from Small Building Retrocommissioning